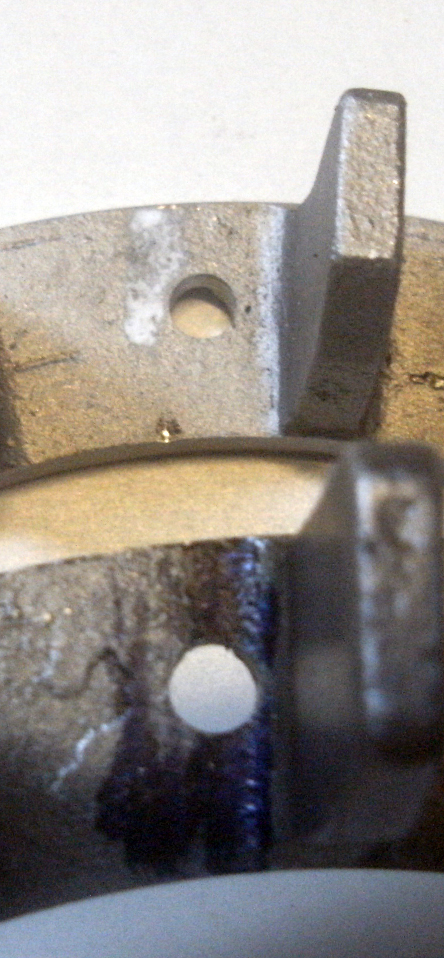

Here is an image of an old industrial engine made by Moteurs Bernard in France in the 1930s. The image was sent by the customer after we completed a gasket order for him. Below the first image is another image showing the ‘art deco’ radiator assembly:

The customer lives in Germany and has one or more of these interesting French engines from the 1930s that he is restoring. I will let him tell the story:

I bought this engine from a french guy who had an auction running on ebay for some other things. He saved it from scrap. It came together with a second engine of that type and both were partially seized and not running. I had to do quite a bit of work, but I got them both running again. The manufacturer is “Moteurs Bernard” and the type W2. This company still exists and produces modern small engines. The engines of this type were made in several sizes and were quite common in France and other countries in Europe during the 1930s. They were also made in a second factory called “C.L. Conord” ( this type as F2) which was overtaken by Bernard and even under license in Germany. At that time the design was quite sophisticated but after the war the more smaller high revving engines came into fashion. As far as I know production of these engines was stopped 1950. Now the special design of the “art deco” style makes them interesting for some enthusiasts.

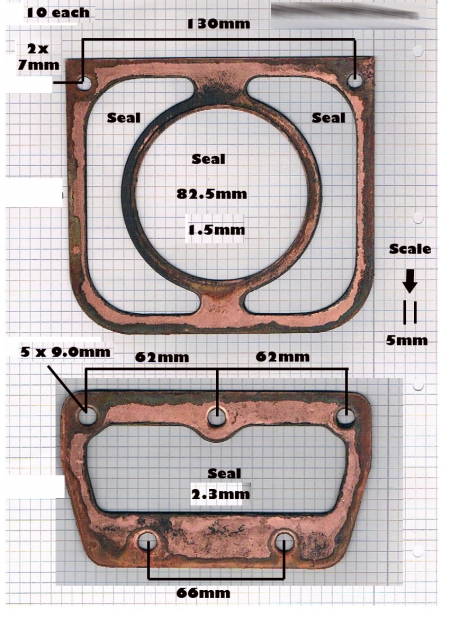

Below you will find an image of the ‘art deco’ radiator:

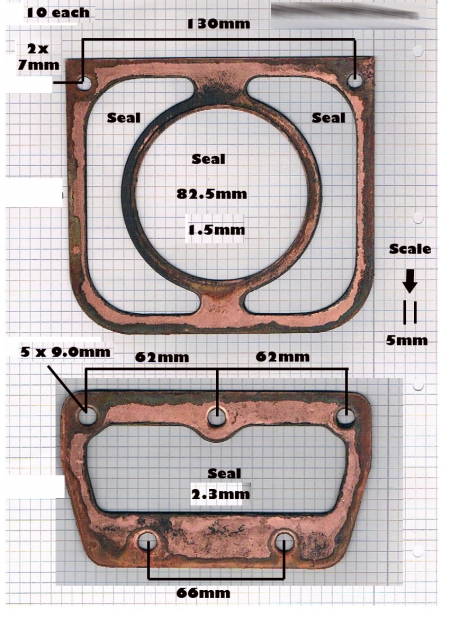

To make the gaskets the customer sent a scan with dimensions drawn in. The graph paper backing allows us to check all the dimensions. We used this scan to produce the gaskets shown immediately below this image. Incidentally, if you are thinking of having us make some gaskets for you or want to obtain a quotation, you can find more info on making scans at www.gasketstogo.com/scans.htm.

These were copper sandwich style construction just like the originals, using a non-asbestos filler material supplied by Interface Solutions (USA) since the EU does not allow that.